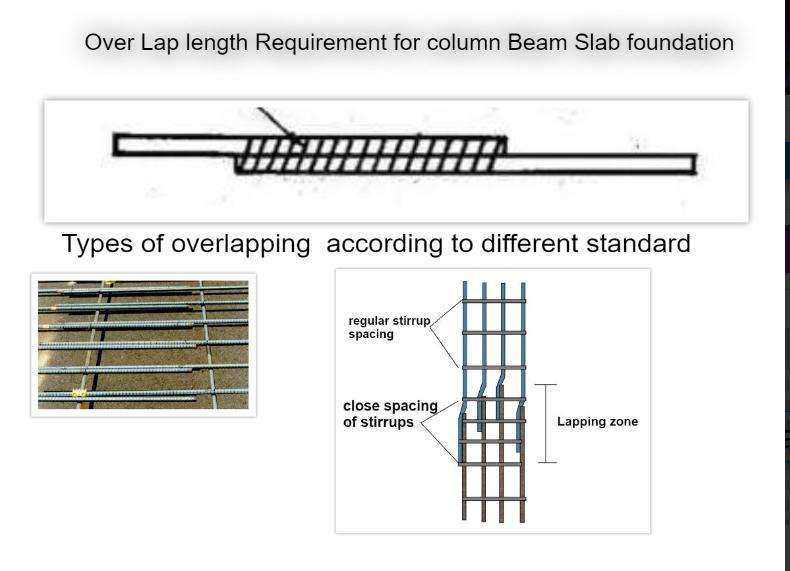

Over Lap length Requirement for column Beam Slab Foundation

In construction, lapping involves overlapping reinforcing steel or rebar sections to enhance the strength and stability of concrete structures. This practice is prevalent in building foundations, walls, columns, and structural elements to safeguard against stress or load-related failures. Moreover, you accomplish lapping by overlapping rebar ends and securing them with wire ties or other fastening methods.

Purpose of Lapping in Reinforcement bar

The purpose of lapping in reinforcement bars is to maintain the strength and durability of a reinforced concrete structure by joining two bars together. This is necessary to ensure that the bars can resist tension and compression forces effectively. The lapping length of the bars should be sufficient to maintain the bond strength between the rebar and the surrounding concrete. You can achieve it through either an overlap or a mechanical connection. Adequate lapping is essential to prevent the premature failure or collapse of the structure.

Types of Lapping According to Position in Reinforcement bar

There are two most important types of lapping used for reinforcement bars in concrete production: the give up-to-quit lapping and the overlap lapping.

- End-to-end lapping: In quit-to-quit lapping, you join two reinforcing bars by setting them quit-to-quit. And then bind them collectively the usage of wire or mechanical connectors. People generally use this sort of lapping whilst the desired length of the reinforcement bars exceeds the same old manufacturing lengths.

- Overlap lapping: In overlap lapping, one reinforcing bar extends beyond the other, and you bind them together with wire or connectors. This is used for standard length reinforcement bars.

In overlap lapping, the determination of the overlap length is based on factors such as the bar diameter, load type, and specific code requirements. Building codes typically specify a minimum overlap length, which varies depending on the type of bar and the applied load.

In general, both end-to-end and overlapping techniques create a strong and reliable joint between two reinforcing bars. This ensures that the concrete structure remains durable and capable of withstanding its intended loads. Such a robust connection is of paramount importance, especially in high-stress areas and when addressing significant environmental factors and corrosion concerns.

Over Lap length

The lap length is the minimum required overlap length between two reinforcing bars. Design drawings specify the overlap length, which typically ranges from 30 to 50 times the bar diameter, based on the reinforcing bar diameter, steel yield strength, and design load, as per standards.

Types of Over lap in Length

There are several types, its depending on design size load,

Lapping Length in Compression Members

- ACI Standard: ACI 318-14: Lapping length for compression members is 24 times the bar diameter.

- IS Standard: IS 456-2000 specifies that the lapping length for compression members is likewise 24 times the bar diameter.

Lapping Length in Tension Members

- ACI Standard: ACI 318-14: Lapping length for tension members is 40 times the bar diameter.

- IS Standard: IS 456-2000: Lapping length for tension members is 30 times the bar diameter.

1. over Lap Length for Column

ACI recommends that the over lapping length for columns should be a minimum of 40 times the bar diameter.

Indian Standards suggest that the lapping length for columns should be a minimum of 45 times the bar diameter.

2. Over Lap Length for Beam

ACI recommends that the over lapping length for beams should be a minimum of 40 times the bar diameter.

Indian Standards suggest that the over lapping length for beams should be a minimum of 45 times the bar diameter.

3. Over Lap Length for Slab

ACI recommends that the lapping length for slabs have to be at least 12 inches or 30 times the bar diameter, whichever is more.

As in line with the Indian Standard code IS 456:2000, the minimum lapping duration for bars in anxiety shall be 50 instances the diameter of the bar, but not much less than 500 mm. However, this can range based on specific undertaking requirements and design issues.

Furthermore, in high-stress zones, such as those located near supports or points of concentrated loading, there may be a requirement for a higher lapping length to ensure the structural strength is maintained. Similarly, in seismic zones, an increased lapping length may become necessary to enhance the structure’s resistance against the formidable forces of earthquakes.

4. Over Lap Length for Foundation

The lapping length of reinforcement bars in foundations varies depending on factors. like the foundation type, bar diameter, steel grade, concrete quality, and anticipated foundation loads.

ACI: Recommends that the lapping length for foundations should be a minimum of 40 times the bar diameter.

Indian Standards: suggest that the lapping length for foundations should be a minimum of 45 times the bar diameter.

furthermore, it is imperative to consider the necessity for extending the lapping length to enhance stress transfer, particularly in regions of exceptionally high stress or when there are substantial concerns regarding the corrosive effects and environmental impact on the structural integrity of the construction.”

Read More