Base Course and Specification and Construction and Method

Base Course and Specification and Construction and Method, Roadway paving serves multiple purposes, including providing a surface for traffic, supporting traffic loads, and guiding surface water into the drainage system for removal. Materials vary in the extent to which they exhibit these characteristics, which is why base and surface courses are separately constructed, even though they form a cohesive unit. The base course, placed atop the sub-base, provides support to the surface course and transfers traffic loads onto the subgrade.

The thickness of the base course varies based on the design load and the material’s characteristics. The completed base may consist of more than one layer, separately placed and compacted. For any base course or surface course to perform effectively, it requires sufficient support from the underlying sub-base and sub-grade. The sub-base must maintain the correct line, grade, cross-sectional shape, and compaction. If there are defects or damage in the sub-grade or sub-base, it must be rectified before placing the base.

The base is the structural component of the flexible pavement which adds to its stability. The base course directly receives the traffic loads from the wearing surface and has, therefore, to be strong enough to resist the effects of loading and weather. The minimum prescribed CBR is 80% for stability and prevention of water soaking through the base. It has to be as dense material as possible. The practice of using un-graded large-size stone particles with significant voids in the base course should be discontinued. Such materials not only permit water ingress but also induce internal movement under traffic, resulting in deformations and settlements.

Generally, crushed stone or water-bound macadam is recommended for base courses. Many pit run gravels, when employed in the base course, may fail to attain the necessary CBR (California Bearing Ratio) value without the addition of a stabilizing agent like cement. Similarly, you can use soil-aggregate mixtures or local silty soils in combination with cement, lime, or asphalt stabilization, as long as you compact them to attain a relatively high density.

However, considering current working conditions and available equipment, crushed stone or angular bases will remain the primary choice. These base courses are categorized as either dry-bound or water-bound macadam, depending on the construction method. Dry-bound macadam denotes a crushed stone base course that gains its strength by grain-to-grain contact through interlocking by rolling or vibration.In water-bound macadam, you add water after incorporating the fines, and then you roll the entire mass. Stability results from grain interlock and the cementation of fine fractions. Penetration macadam involves spreading bituminous materials over the stone aggregate and allowing them to penetrate mass. Base Course and Specification and Construction and Method

Materials

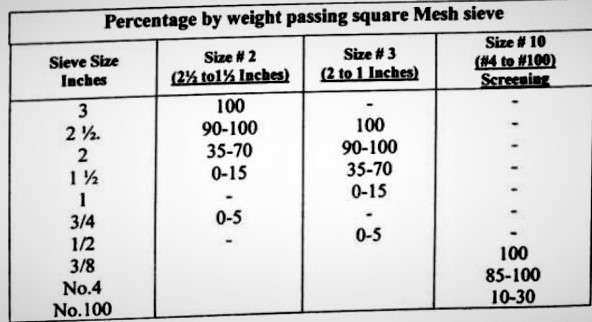

The materials required for macadam bases are well-graded crushed stone and screening which are used to fill the voids in the compacted layers. The maximum size of the largest stone particles in the selected gradation of the material should be between half to two-thirds of the thickness of the compacted layer (by taking 4 1⁄2 compacted layer). Brief specifications of the materials are given below. Base Course and Specification and Construction and Method

Specifications for Base Material

The base course material must meet well-graded specifications in accordance with AASHTO M-43/ASTM D-448 when tested using laboratory sieves. The designated size must conform to the following requirements.

The crushed stone shall consist of clean, tough, durable fragments, free from any excess of flat, elongated, soft, and disintegrated pieces. Do not use shale, phyllite, slate, or schist as base course material due to their tendency to produce excessively elongated particles. The screenings shall be of suitable binding quality and conform to the sizes mentioned. The crushed stone must meet the following conditions:

Sr. No. Test Property Specified limits

i Los Angeles Abrasion value % (Max) 40

ii Bitumen Adhesion % (Max) for top layer Above 95

iii Flakiness and Elongation (BS-812) (Max) 35

iv Soundness % (Max) 12%

v Water Absorption % (Max) 2

General Construction Base Course Material

The base course is crucial for load-bearing in highway and road construction. The durability and ride quality of the surface depend on its construction quality. It can constitute either a single layer or multiple layers added above the sub-base, sometimes incorporating additional materials mixed into the upper sub-base to a specific depth. The Inspector ensures proper construction methods are followed in this process.

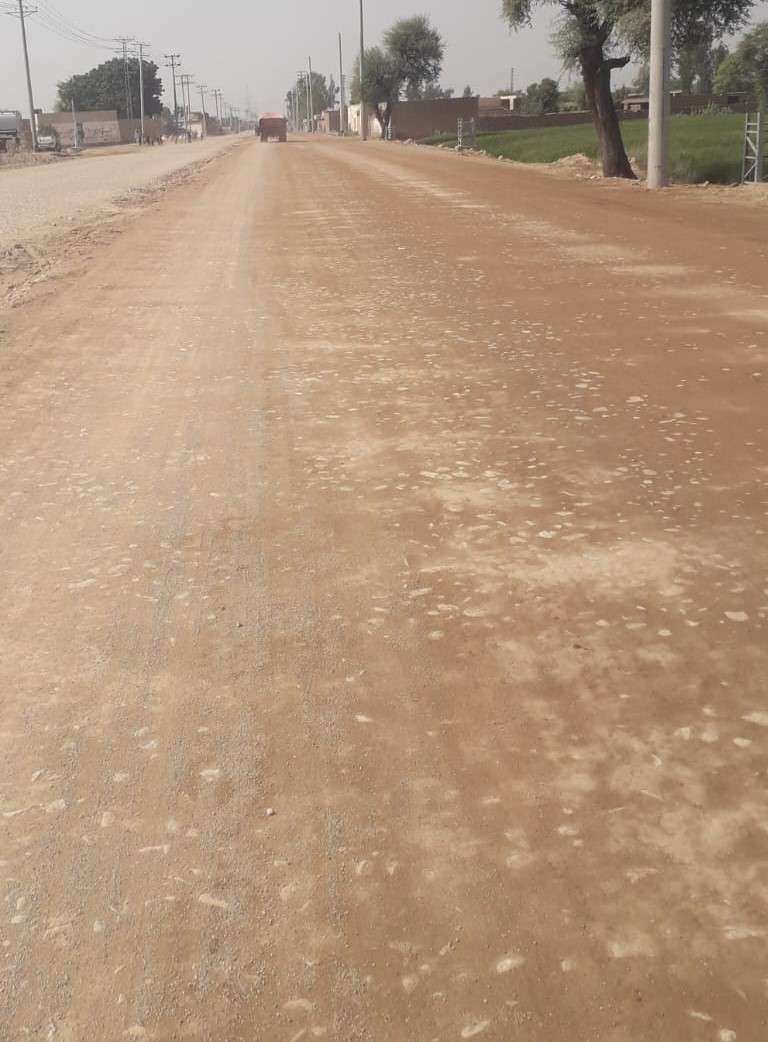

Prepare the sub-base for the full base width as specified on the Plans. Thoroughly compact and construct it to match the alignment and grade indicated on the Plans. Defective areas in the sub-base, if not corrected, will ultimately appear on the surface of the finished road. Ruts are especially likely to channel subsurface water, resulting in damage to the road.

Before placing base course material, the Contractor must set line and grade for the top lift of any base course with fixed controls not to exceed 25 feet longitudinal spacing and 25 feet transverse spacing. The top lift of any base course must not deviate more than 3/8 inch from the grade established. The marks on the stakes should show the grade at the top of the base course.The Inspector should meticulously ensure the uniformity of each layer’s surface during construction. The Inspector should carefully attend to achieving a uniform surface on each layer as they are being constructed. The Inspector must ensure the correct crown is in place where required and prevent any longitudinal waves from appearing on any course.

Do not allow the construction of a base course on a rutted sub-base. Rutting typically happens due to excessive moisture or inadequate compaction of the sub-base. The Contractor should limit the weight and speed of equipment to prevent damage when hauling over the sub-base course.

Construct shoulders or berms at least 24 inches wide on both sides of the base, extending to the top of each course unless adjacent to concrete curbs or gutters. This provides edge support for the base course and enables the roller to overlap the shoulder during compaction. Uniformly spread, shape, and compact the specified base material. Ensure that you do not mix the shoulder or berm material with the base course during these operations.

If the subgrade material becomes churned up and mixed with the base course, the Contractor shall remove and restore that section of the roadway. Do not place any base course material on a wet, spongy, frozen, or rutted sub-base. Shape the smooth surface meticulously to the desired level and maintain it properly, ensuring there are no bumps or grooves. After placing the base course but before finishing the shoulder or median areas, construct subgrade drains as specified in the Specifications

WBM (Water Bound Macadam) Construction

The most common method of base course construction is water-bound macadam (WBM). Use an all-in-run aggregate/granular base course, mixed with the fine fraction, at the optimum moisture content (OMC). Ensure the sub-grade or sub-base reaches the desired compaction level before starting base course construction. Base Course and Specification and Construction and Method

(1) Placing and Spreading

For Subgrade and base course preparation, choose crushed stone aggregate within specified gradations. Ensure the largest stone particle size is between 1/2 to 2/3 of the proposed compacted base course thickness (typically 4 inches). Spread the crushed stone directly from trucks using spreading boxes or from roadside stone aggregate stacks. Typically, loose crushed stone settles to about 20-25% less thickness, depending on gradation and stone type, so consider this when laying the loose layer for base course preparation. Screenings of Size #10 AASHTO M-43 can fill the voids within the aggregate without altering the overall volume.

(2) Rolling

Prior to commencing rolling, eliminate surface irregularities through manual packing and make ample use of templates and long straight edges to check the camber, side slope, and surface uniformity. Irregularities are much easier to correct in the loose layer than later on in the compacted form. In the initial phase, rolling employs an 8 to 10-ton smooth wheel roller. Typically, rolling begins at the edges and advances towards the center, with the roller continuously moving longitudinally. The roller passes are carried out in a manner that ensures full surface coverage, overlapping as needed. Rolling generally continues until the material no longer creeps or forms waves in front of the roller. However, it’s important to avoid excessive rolling at the beginning to prevent crushing the material before applying screenings. Any surface irregularities in the crushed stone layer are rectified during rolling, using additional stone aggregate as necessary.

(3) Addition of Screening and Rolling

The next step is the application of stone screening or choking material in the course layer. You can lay the stone screenings using either a mechanical spreader or manual labor. Typically, spreading, brooming, and rolling operations are simultaneously conducted in conjunction with each other. Apply screenings until they fill the surface voids of the coarse layer, and then use fiber or wire brooms attached to the roller units by wire broom draggers or by hand to broom the screening into the voids. Continue rolling as before while spreading and brooming until the surface achieves a firm and thorough compaction. Additional screenings may be added as needed till no more screenings penetrate the voids.

(4) Water and Wet Rolling

After applying stone screenings and dry rolling, moisten the layer’s surface with water. Continue rolling until voids fill and a grout wave flushes ahead of the roller. Ideally, use a pressure distributor attached to a water lorry’s pneumatic tires for water application. Evenly distribute wet stone screenings with a hand broom. The quantity of water and screenings depends on factors like crushed stone size and nature, screening characteristics, and desired surface type. Remove excess fine material before laying the subsequent base course or surfacing. Avoid excessive water use in water-bound macadam base construction to prevent sub-base and subgrade softening, which can lead to failure.

(5) Layer Thickness

The compacted thickness of any layer of the base course should not be less than 3 inches and 4 inches more than 6 inches with smooth wheel roller but with vibratory compactors a compacted thickness of the layer can be up to 8 inches. However, keeping in view present working conditions and the available compaction equipments. The thickness of the compacted layer should not exceed 4%1⁄2 inches. If the contractor can satisfactorily demonstrate the ability to achieve compaction in a 6-inch thick layer using specialized rolling equipment, they may receive permission to do so from the engineer.

(6)Curing and Application of Second Course

If the finished layer functions as the bottom or intermediate course in a multiple-course water-bound macadam, ensure it dries thoroughly before proceeding to add the next course. Once this course has cured satisfactorily, proceed to place the next layer, following the same procedure as previously.

(7) Checking of the Surface

After completing the top course, inspect the surface for deviations exceeding 1/2 inch using a 10-foot straight edge. Correct any irregularities in accordance with the specified cross sections and longitudinal grade to ensure compliance with the 1/2 inch tolerance limit.

(8) Curing of Water Bound Macadam

Normally, water-bound macadam cures under traffic for at least 7 days before the bituminous surface is applied. If needed, perform additional screenings, sprinkling, and rolling during this period to ensure adequate surface binding. Before applying the bituminous surfacing, make sure the finished surface is completely dry and clean.

Use of Vibratory Compactors

The use of vibratory compactors has become obligatory for the compaction of base courses. Self-propelled models increase the extent of use, but the use of combination rollers, such as vibratory drums with pneumatic tires, is very common. In vibratory rollers, the variable amplitude is a valuable feature for base compaction. Using a maximum amplitude is effective for compacting the lower part of a base, whereas a lower amplitude is more suitable for the top layer. When materials become exceptionally hard at higher densities, they can make vibratory rollers “bounce.” In such cases, switching to a lower amplitude for the final roller passes is often beneficial.

Vibratory road foot rollers can crush fine rock pieces. Compacting crushed stone layers involves several procedures. In one method for an 8-inch macadam base, crushed stone is spread in an 11-inch loose layer. Initially, a heavy smooth wheel roller compacts this loose layer, facilitating the vibrator’s passage over the crushed stone. Subsequently, the layers undergo two passes with a heavy multiple-shoe vibrator to establish the keying of the lower 2/3 of the layer. Finally, the upper 1/3 is keyed using a smooth roller.

These vibrators are also very effective in the application of screening. To fill an 8-inch base course, you can accomplish it in just three applications of stone screenings. For the initial application, evenly spread half of the required screenings to fill the 8-inch base course over the keyed and completed stone aggregate layer. You can achieve this using a mechanical spreader or manual methods. Make one or two passes with the vibrators, depending on the crushed stone size. Then, apply 1/4 of the screenings and subject it to one pass with a vibrator. Follow this by spreading the remaining screenings and conducting an additional pass with the vibrator. Afterward, proceed with rolling, adding fines as needed, and applying water in the final stage.

The Vibratory rollers ensure uniform screenings distribution. Promptly fill voids in crushed stone layers with screenings after initial operations to prevent extended unfilled sections. This prevents rainwater infiltration, which could soften the sub-base and sub-grade.

Read More

What is a superelevation in the road